Corrosion protection systems provide safeguards to the steel components of the ground anchors. The system consists of some components that are attached to each other to provide the complete safe barrier to the anchor tendon and total ground load transitions between them. Ground anchors of steel components are mainly bearing plate, head, prestressing steel, trumpet, and couplers.

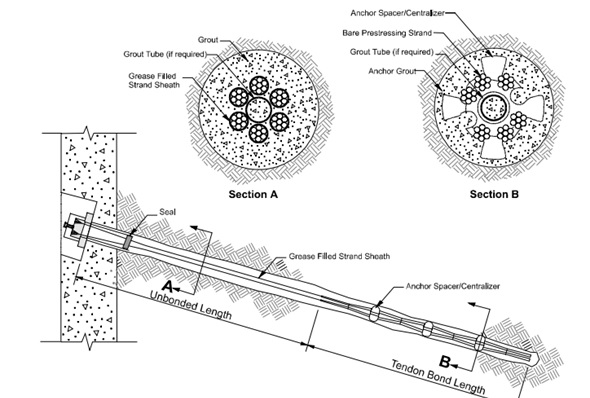

Source: FHWA-IF-99-015/ ground anchors and anchored systems

Single Corrosion Protection Anchor

The single corrosion protection anchor has components which include:

- Anchorage: This includes the top cover (anchorage cover), concrete wall embedded with corrosion prevents component or grout, and trumpet.

- Anchorage cover: The main aim is to protect the exposed prestressing bars from corrosion, physical damage and protect the anchor top head.

- Trumpet: Trumpet provides the protection of prestressing steel bars in the unbonded length of anchor (provided from the backside of bearing plate to the terminated portion of unbonded length), which is manufactured with PVC pipes or steel material.

- Corrosion prevention compounds: These compounds are greases and waxes, which protect the prestressing steel bars in the zone of anchorage and unbonded length.

- Unbonded length: This includes the grout, sheath filled with corrosion prevention compounds.

- Grout: This is the main common part in unbonded and bonded length. Cement-based grout protects the prestressing steel bars. Grouts are used in covers, sheaths, trumpets. Resin-based gouts are not used in corrosion protection anchors because the resins corrode and hence unprotect the steel bars.

- Sheaths: These are tubular plastic and smooth pipes. The main function is the protection of prestressing steel bars in unbonded length portions. Protection of prestressing steel bars is done with corrosion prevention compounds such as greases or waxes and is filled with grout around tendon sheaths. These smooth sheaths work as bond breakers.

- Bonded length: This includes the grout, centralizers with sometimes epoxy coating of grout.

- Centralizers: These are commonly finished with steel or plastic, which support the tendons in drill holes and maintain their position in the center.

In a Single corrosion protection anchor, the anchorage (unbonded length) assumes that the ground condition is aggressive and requires the multiple-barrier layers that provide coverage to the tendon. Only one barrier in the form of a grout layer is used in bonded length, which is workable only under non-aggressive ground conditions. Therefore, this type of anchorage system is used as temporary anchors for life up to 2 years and some more.

Applications:

- Temporary tiebacks

- Excavation supports

- Stabilizations for stage constructions

- Anchor in non-aggressive conditions of ground

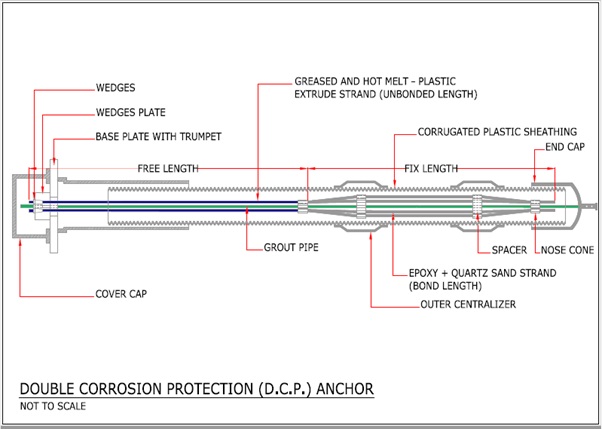

Double Corrosion Protection Anchor

In Double corrosion protection anchor, for the anchorage (unbonded length) and fixed length, it is assumed that ground condition is aggressive and requires the multiple-barrier layers as proving material in the tendon for unbonded length. In addition, Encapsulate tendons are composed of individual grease-filled strand sheaths with grout-filled smooth sheaths used in unboned length. For bonded length, it is also assumed that there is an aggressive ground condition so that multiple barrier layers with encapsulation are provided across the full length.

This type of anchorage system is used as a permanent anchor.

- Used as a permanent anchor, which means last for a long duration. (up to 100 years)

- Encapsulations, corrugated sheathing is used in both unbonded and boned length portions.

- Double corrosion protection is achieved by using both encapsulations with strands that are greased and are individually protected.

Applications:

- Uplift control

- Toe stabilization

- Rock stabilization

- Positional stability